DF-TOOLS SERIES

Polishing, deburring, rounding or smoothing: We build drag finishing systems to finish any surface quickly and affordably. From small series production to large-scale industrial manufacturing.

Polishing, deburring, rounding or smoothing: We build drag finishing systems to finish any surface quickly and affordably. From small series production to large-scale industrial manufacturing.

|

Equipment:DF-TOOLS SERIES |

|

|

We get you to the finish with μ precision.In series production, reliably repetitive results and costeffectiveness deliver a real competitive edge.

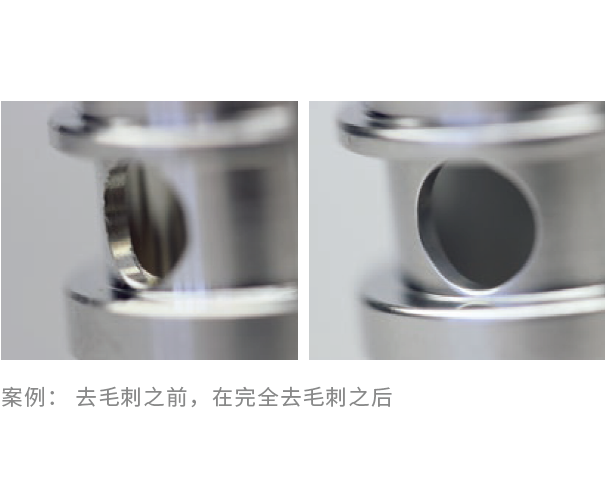

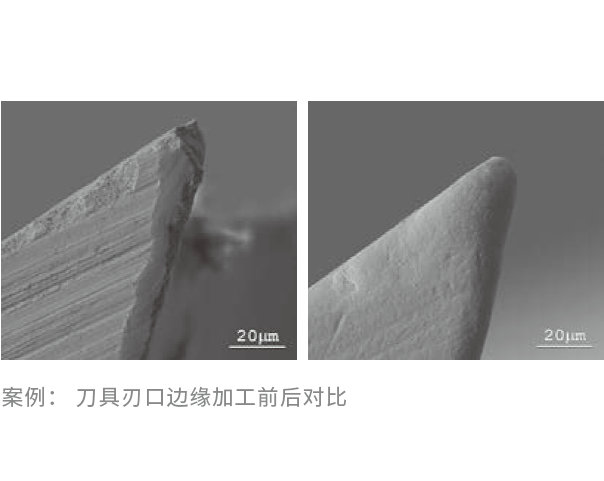

| Deburring | Rounding |

|

|

| Residual burring and swarf from the manufacturing process on the edges and surfaces impair the quality of a workpiece. By choosing the right media and the right process, these blemishes can be removed to give trouble-free downstream finishing and better handling. | Edges are generally rounded in order to improve the reliability of a workpiece. A rounded edge is free of burrs, has no secondary burring and is therefore less susceptible to wear and chipping. |

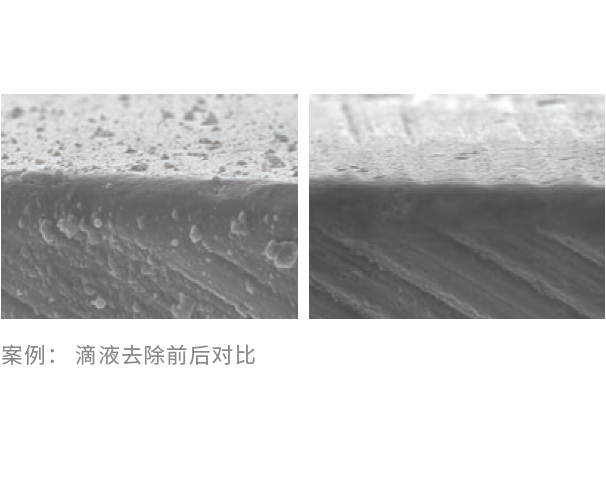

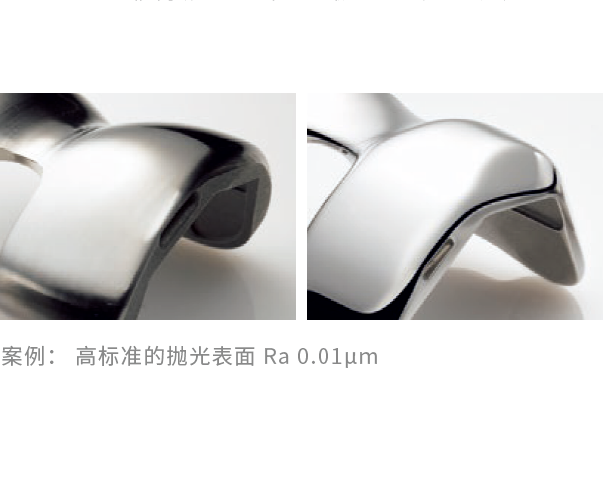

| Smoothing | Polishing |

|

|

| With smoothing, the roughness of the surface is reduced, i.e. the unevenness in the peaks on the surface are removed. The benefits this brings include reduced friction, higher contact ratios and less wear. A further benefit is the removal of droplets after PVD coating. | In addition to improving the appearance of the workpiece surface, polishing also improves the physical properties of the surface. For example, an absolutely smooth and scratch-free surface increases the life of implants and in the case of cutting tools, a polished chip flute gives higher maximum cutting speeds. |

Genuine components for a genuine system

Machine + holder + process + workpiece. The whole is more than the sum of the parts. In order to deliver perfect results, holders and machines must be tested together and carefully coordinated.

Our workpiece holders make a significant contribution to the perfect processing results obtained by the DF series.

ZOTEC’s proprietary tool holders ensure that the workpieces are mounted as quickly and effectively as possible and considerably speed up batch processing. In recent years, we have designed over 100 different types of holder in close cooperation with our customers. In particular, optional features such as laser-operated immersion depth control benefit the absolute compatibility of holder and machine.

| Independently driven angled holder | Rigid holder |

|

|

| Optionally available with the holder adjustable at an angle for finishing end surfaces and complex geometries. | Rigid holder with quick tool changer Customized |

| Quick tool changer | Customized holders |

|

|

| This system enables tools such as drills and burs to be changed in seconds by means of lever. | On request, we can develop special tool holders to meet your specific requirements. |